Products

-

Graphite crucible

High-purity graphite crucible has good thermal conductivity and high temperature resistance. In high temperature use, the coefficient of thermal expansion is small, and it has a certain resistance to rapid heat and cold. It has strong corrosion resistance to acid and alkali solvents and has good performance. The chemical stability. High-purity graphite crucibles have a wide range of applications, mainly used to smelt various silver, aluminum, lead, copper, zinc and other non-ferrous metals, medium carbon steel and rare metals. The high-purity graphite crucible has stable quality and long service life, greatly reduces fuel consumption, reduces labor intensity, improves labor intensity, and creates better economic benefits.

-

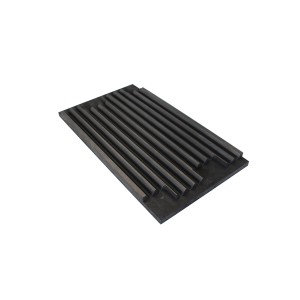

EDM graphite

EDM graphite, also known as graphite for electric discharge machining, is a new type of material, which is now more and more widely used in the precision mold processing industry. At present, in mold processing plants in developed European countries, more than 90% of mold processing electrode materials are graphite. Copper, once the dominant electrode material, has almost disappeared its advantages compared with graphite electrodes. Why is this so? Because graphite has a huge advantage as an electrical discharge material for EDM, since spark oil also contains C atoms, during electrical discharge machining, the high temperature causes the C atoms in the spark oil to be decomposed, thereby forming a protective film on the surface of the EDM graphite electrode , The loss of graphite electrode is compensated, so the loss of graphite electrode is very small, so the service life is long.

-

Graphite mold for continuous casting

Continuous casting graphite mold refers to graphite products used in continuous casting molds. Metal continuous casting technology is a new technology that directly turns molten metal into a material through a continuous casting mold. Because it does not undergo rolling and becomes a material directly, the secondary heating of the metal is avoided, so a lot of energy can be saved.

-

Square graphite boat

Square graphite boat The graphite boat is a kind of graphite mold, using as a carrier, which can put the raw materials and parts that we need to position or shape together in the graphite mold for high-temperature sintering. The graphite mold is made of artificial graphite blocks by mechanical processing. Graphite boats are also called graphite boxes, graphite saggers, and graphite molds. Performance characteristics of graphite boats, graphite boxes and graphite molds for powder metallur... -

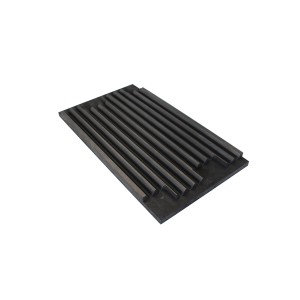

Graphite plate

Graphite plate(graphite boat) adopts high-quality graphite material, adding organic compound with strong acid resistance. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment. It has extraordinary acid and temperature resistance. It is an ideal lining material for phosphoric acid reaction tanks and phosphoric acid storage tanks in the chemical industry. The product has the characteristics of wear resistance, temperature resistance, pressure resistance, corrosion resistance, creep resistance, oil-free self-lubrication, small expansion coefficient, and superior sealing performance.

-

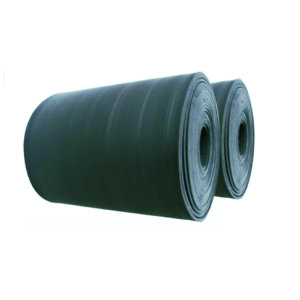

Graphite felt

Graphite felt is divided into pitch-based graphite felt, polyacrylonitrile-based (PAN-based) graphite felt, and viscose-based graphite felt due to the different selection of original felts. The main purpose is to be used as heat preservation and heat insulation materials for monocrystalline silicon smelting furnaces. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents.

Carbon felt is graphite felt after being treated at a high temperature of over 2000℃ under vacuum or inert atmosphere. The carbon content is higher than that of carbon felt, reaching more than 99%. At the end of the 1960s, graphite felt was already available in the world. Graphite felt is divided into pitch-based, polyacrylonitrile-based graphite felt and viscose-based graphite felt due to the different selection of the original felt.

-

Graphite Boat for Lithium iron phosphate battery

Graphite boat(graphite boat) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite boat is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite boat, sometimes it’s called a graphite box. The graphite boat is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitridation furnaces, tantalum niobium smelting furnaces, vacuum quenching furnaces, etc.

-

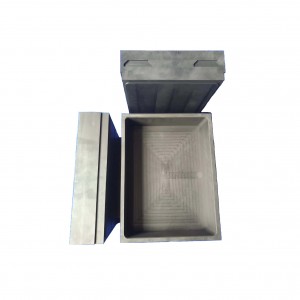

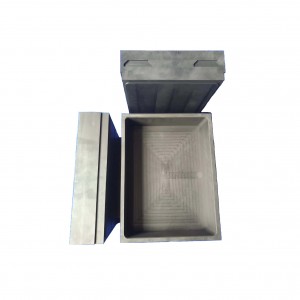

Graphite Box for anode powder

Graphite box (graphite boat) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite box is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite box, sometimes it’s called a graphite boat. The graphite box is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, ion nitridation furnaces, tantalum niobium smelting furnaces, vacuum quenching furnaces, etc.

-

Molded Graphite

The fine grain graphite block produced by cold molding is widely used in machinery, electronics, semiconductors, polycrystalline silicon, monocrystalline silicon, metallurgy, chemical, textile, electric furnaces, space technology and biological and chemical industries.

The graphite has the following characteristics:

- Good electric conductivity and high thermal conductivity

- Low thermal expansion and high resistance to thermal shock.

- The strength increases at high temperature, and it can withstand over 3000 degrees.

- Stable chemical property and hard to react

- Self lubrication

- Easy to process

-

Isostatic graphite

Isostatic graphite refers to graphite materials produced by isostatic pressing. Isostatic graphite is pressed uniformly by liquid pressure during the molding process, and the obtained graphite material has excellent properties. It has: large molding specifications, uniform blank structure, high density, high strength, and isotropy (characteristics and dimensions, The shape and sampling direction are irrelevant) and other advantages, so isostatic graphite is also called “isotropic” graphite.