High Quality Heat Exchange Graphite Block - Machined graphite block for processing exothermic welding graphite mold – Ningxin

High Quality Heat Exchange Graphite Block - Machined graphite block for processing exothermic welding graphite mold – Ningxin Detail:

Technical Characteristic

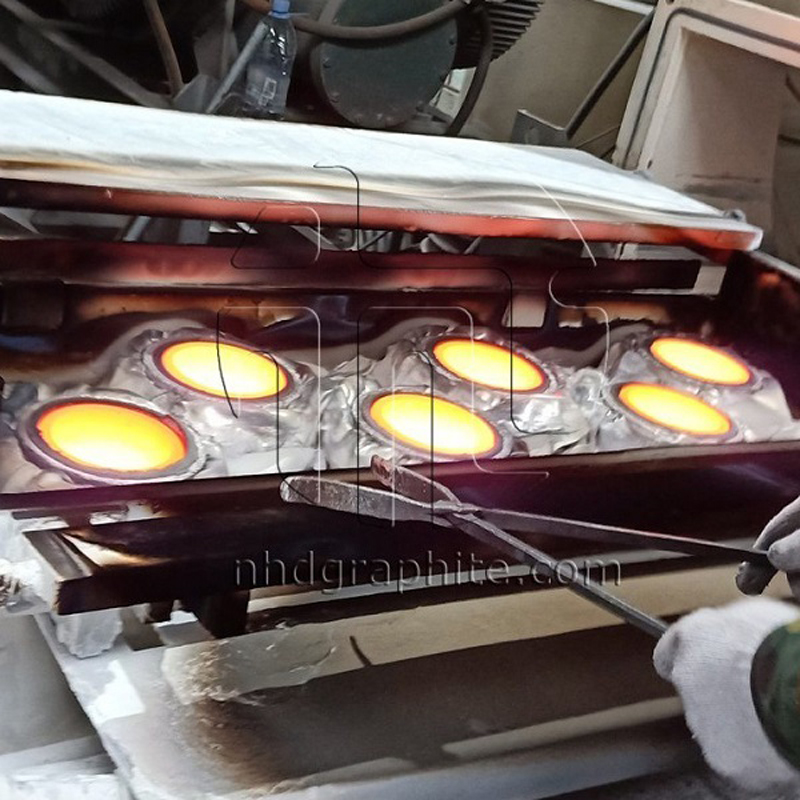

1. Exothermic welding

Exothermic welding is a simple, high-efficiency, and high-quality metal joining process. It uses the chemical reaction heat of metal compounds as a heat source, and directly or indirectly heats the overheated (reduced) molten metal to work in a special graphite mold. A welded joint of a certain shape and size is formed in the cavity to meet the engineering requirements. At present, exothermic welding has generally replaced the previous mechanical connection method between metals.

2. Application fields of exothermic welding

1. Lightning protection, grounding and surge protection.

2. Electrical equipment grounding engineering treatment.

3. Petrochemical engineering construction.

4. Construction of railways, highways, and airports.

5. Intelligent building construction.

6. Cathodic corrosion protection.

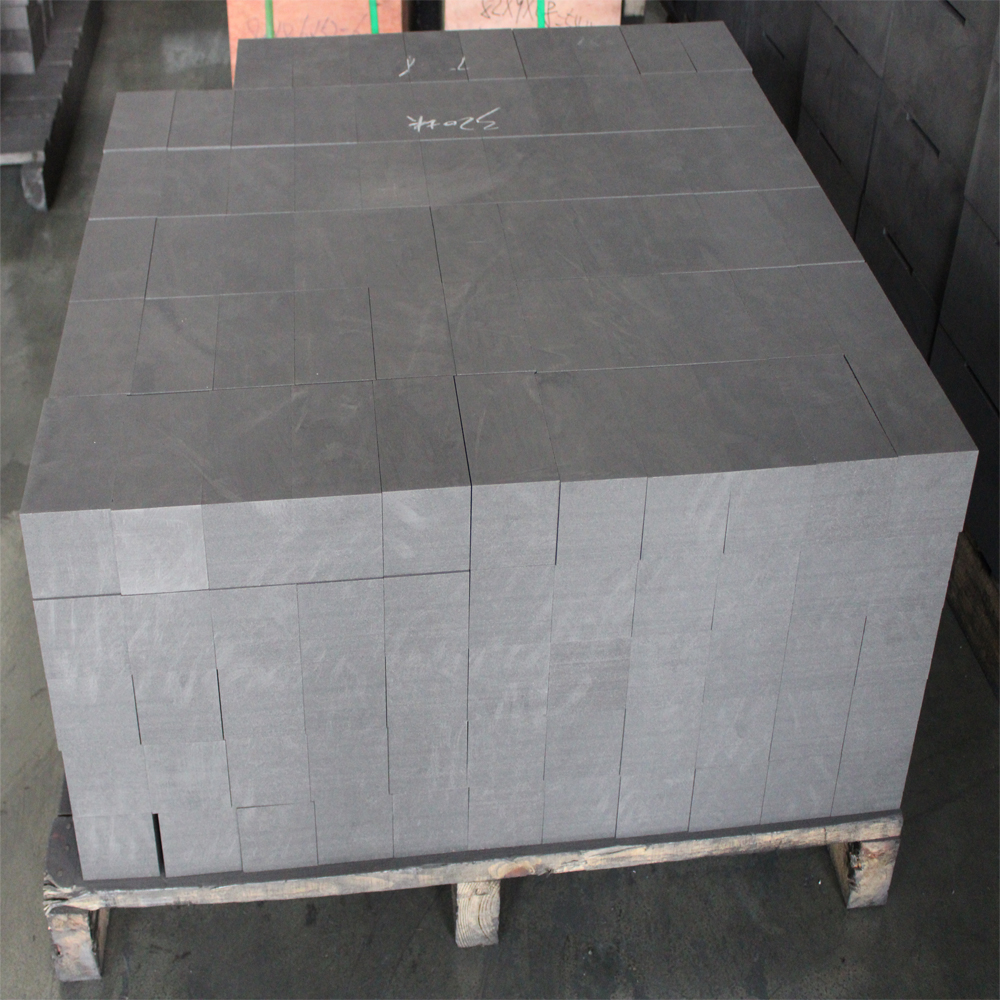

3. Processing graphite block (semi-finished product)

Jiangxi Ningheda New Material Co., Ltd. is a manufacturer specializing in graphite finishing, with advanced processing technology and strong processing capabilities. It is widely praised by customers at home and abroad. The graphite products processed by our company have been unanimously recognized by customers. In response to the requirements of the majority of exothermic welding customers, our company can also process semi-finished graphite blocks for customers, which greatly shortens the delivery time of customers.

Product Size

Specifications of most popular graphite for processing exothermic welding molds are as follows:

Grade: NX82

Grain size(≤): 0.8mm

Bulk Density(≥): 1.72g/cm3

Ash (≤): 0.3%

Specific Resistance ≤8.5μΩM

Compressive Strength ≥35MPa

Flexural Strength ≥13.5MPa

Coefficient of Thermal Expansion ≤2.2×10-6/℃

Grade: NX603

Grain Size(≤): 25μm

Bulk Density(≥): 1.80g/cm3

Compressive Strength(≥): 60MPa

Flexural Strength(≥): 30MPa

Porosity(≤): 17%

Specific Resistance(≤): 12μΩm

Ash Content(≤): 600ppm

Shore Hardness: 50

Coefficient of Thermal Expansion(≤): 5×10-6/℃

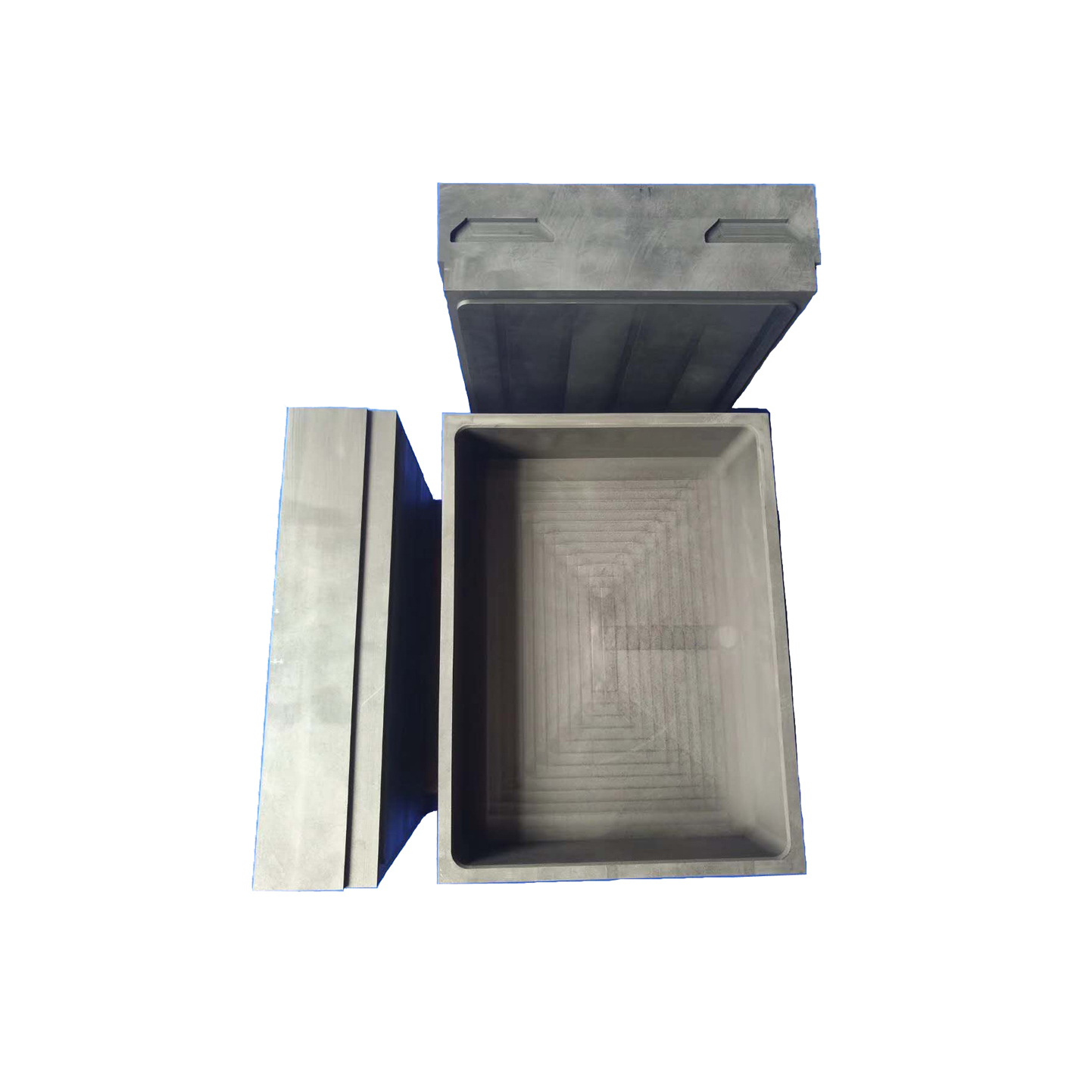

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for High Quality Heat Exchange Graphite Block - Machined graphite block for processing exothermic welding graphite mold – Ningxin , The product will supply to all over the world, such as: Hungary, United Arab emirates, Moldova, With the superior and exceptional service, we've been well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!