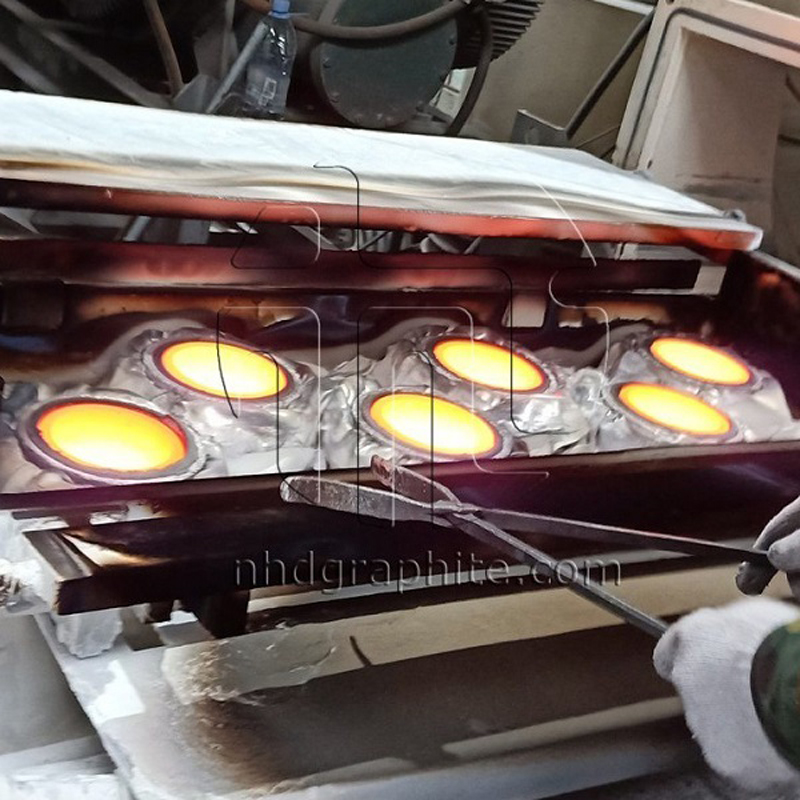

Graphite crucible

Ningheda Graphite material Advantages

1.Graphite raw material has high bulk density and low porosity, which resists the erosion of molten aluminum liquid and gaseous aluminum particles to the greatest extent.

2.Graphite raw material with high purity, low ash content prevents volatile substances in production, avoiding spots, holes on aluminum coated film, which can guarantee the quality of the aluminum coated film.

3.Graphite crucible has precise dimensions, smooth surface, strong oxidation resistance, low consumption and long service life.

Technical Index

| Grade |

Grain Size (≤mm) |

Bulk Density (≥g/cm3) |

Compressive Strength (≥MPa) |

Flexural Strength (≥MPa) |

Porosity (≤%) |

Specific Resistance (≤μΩm) |

Ash content (≤%) |

Shore Hardness |

|

NX605 |

25 |

1.90 |

70 |

35 |

11 |

12 |

0.08 |

60 |

Advantages of graphite crucible for vacuum evaporation coating of aluminum

1. Thermal stability: According to the use conditions of graphite crucible for rapid heating and cooling, special design is carried out to ensure the reliability of quality;

2. Corrosion resistance: The uniform and fine matrix design delays the corrosion of the crucible;

3. Impact resistance: The thermal shock strength that the graphite crucible can withstand is extremely high, so any process can be carried out with confidence;

4. Acid resistance: the addition of special materials significantly improves the quality of graphite crucibles, has excellent performance in terms of acid resistance indicators, and greatly prolongs the service life of graphite crucibles;

5. High thermal conductivity: The high content of carbon ensures good thermal conductivity, shortens the dissolution time, and significantly reduces fuel consumption or other energy consumption;

6. Control of metal pollution: Strict control of material composition ensures that the graphite crucible does not pollute the metal during dissolution;

7. Quality stability: The technical process and quality assurance system of the high-pressure forming method more fully guarantee the stability of the quality.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).