Welcome to our websites!

Featured

-

Hot-selling Graphite Rod For Electrode - Bottom price Leading China Factory Sale Artificial Graphite Carbon Block for Projects – Ningxin

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is “You come here with difficulty and we give you a smile to take away” for Bottom price Leading China Factory Sale Artificial Graphite Carbon Block for Projects, Welcome mates from all around the world occur to go to, manual and negotiate. we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destin... -

Good Wholesale Vendors Edm Graphite - Bottom price Leading China Factory Sale Artificial Graphite Carbon Block for Projects – Ningxin

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is “You come here with difficulty and we give you a smile to take away” for Bottom price Leading China Factory Sale Artificial Graphite Carbon Block for Projects, Welcome mates from all around the world occur to go to, manual and negotiate. we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destin... -

Super Purchasing for Foundry Graphite Crucibles For Sale - Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering – Ningxin

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering, Using the everlasting aim of “continuous quality improvement, customer satisfaction”, we are sure that our item excellent is secure and responsible and our products and solutions are best-selling at your home and overseas. With our rich experience a... -

factory low price Graphite Crucible For Aluminum - Graphite heater – Ningxin

Technical Characteristic Main performance of graphite heater The oxidation speed and volatilization speed of graphite affect the service life of the heating element. When the vacuum degree is 10-3~10-4 mmHg, the operating temperature should be below 2300℃. In the protective atmosphere (H2, N2, Ar, etc.), the operating temperature can reach 3000℃. Graphite cannot be used in the air, otherwise it will be oxidized and consumed. The thermal expansion coefficient of graphite is small, and the... -

Hot Selling for Graphite Molds For Silver - Molded Graphite – Ningxin

Technical Characteristic Grade NX601 NX602 NX603 NX604 NX605 Grain Size (μm) 25 25 25 25 25 Bulk Density (≥g/cm3) 1.55 1.72 1.80 1.85 1.90 Compressive Strength (≥MPa) 35 45 60 70 80 Flexural Strength (≥MPa) 15 20 30 35 40 Porosity (≤%) 23 20 17 14 11 Specific Resistance (≤μΩm) 14 13 12 12 12 Ash Content (≤ppm) 800 700 600 500 300 Shore Hardness 35 45 50 55 60 ... -

High reputation Graphite Tray - Graphite Blank – Ningxin

Detail usages are as follows 1. For processing graphite crucible, graphite boat, graphite mold, graphite rotor, graphite heating element, graphite flow trough, graphite cold iron, etc.; 2. used for high temperature furnace body to make structural materials; 3. used in strong acid, alkali, strong corrosive environment, such as rare earth smelting, chemical industry, etc., processed into various parts according to needs; 4.For processing graphite electrodes. Technical Characteristic ... -

Popular Design for Continous Casting Copper Graphite Mold China - graphite crucible – Ningxin

Graphite Crucible High-purity graphite has the characteristics of high strength, high density, high purity, high chemical stability, compact and uniform structure, high temperature resistance, high electrical conductivity, good wear resistance, self-lubricating, and easy processing. It is widely used in metallurgy, chemical industry, and aerospace. , Electronics, machinery, nuclear energy and other industrial fields. Especially large-scale and high-quality high-purity graphite, as an alt... -

Good quality Chinese Manufacturer Powder Sintering Graphite Crucible - Graphite Rotor – Ningxin

Graphite Rotor The graphite rotor and graphite impeller are made of high-purity graphite. The surface is treated with special anti-oxidation, and the service life is about 3 times that of ordinary products. It is widely used in aluminum alloy casting industry. The purification process of liquid aluminum alloy is the main method to improve the comprehensive performance of aluminum alloy. In the purification process, the method of mixing the purification gas and the solvent and spraying th... -

Popular Design for Rod Graphite - Graphite Raw Material – Ningxin

Technical Characteristic As the material of exothermic welding mold, graphite has the following characteristics: 1) High temperature resistance: The melting point of graphite is 3850±50℃, and the boiling point is 4250℃. Even if burned by ultra-high temperature arc, the weight loss is very small, and the thermal expansion coefficient is also very small. The strength of graphite increases with increasing temperature. At 2000°C, the strength of graphite doubles. The temperature of the chemi... -

Best Price on Graphite Made Of - graphite crucible – Ningxin

Graphite Crucible High-purity graphite has the characteristics of high strength, high density, high purity, high chemical stability, compact and uniform structure, high temperature resistance, high electrical conductivity, good wear resistance, self-lubricating, and easy processing. It is widely used in metallurgy, chemical industry, and aerospace. , Electronics, machinery, nuclear energy and other industrial fields. Especially large-scale and high-quality high-purity graphite, as an alt... -

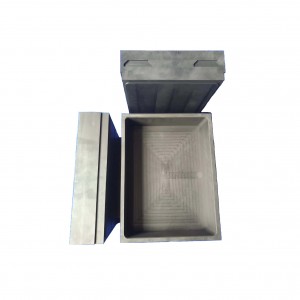

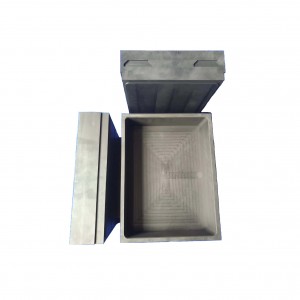

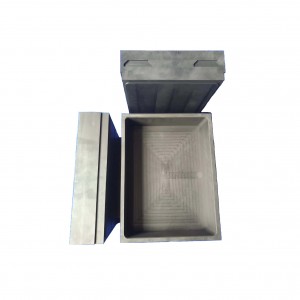

Big Discount Graphite Heating Furnace - Graphite Box for anode powder – Ningxin

Our advantage 1. Thermal stability: for the use of hot and cold conditions, special treatment to ensure the reliability of product quality. 2. Corrosion resistance: uniform and fine material structure, delay the erosion of the use of degrees. 3. impact resistance: the ability to withstand high thermal shock, so the process can be assured. 4.Acid resistance: the addition of special materials significantly improved the physical properties of the material, excellent performance in terms of ... -

Factory wholesale Graphite Jewelry Molds - graphite boat – Ningxin

Graphite Boat Graphite box (graphite boat) itself is a carrier, we can put the raw materials and parts we need to locate or finalize the design together in which high temperature sintering molding. Graphite box is made of artificial graphite by mechanical processing. So sometimes it’s called a graphite box, sometimes it’s called a graphite boat. The graphite box is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, io... -

Factory Price Pure Carbon Crucible - Graphite Rotor – Ningxin

Graphite Rotor The graphite rotor and graphite impeller are made of high-purity graphite. The surface is treated with special anti-oxidation, and the service life is about 3 times that of ordinary products. It is widely used in aluminum alloy casting industry. The purification process of liquid aluminum alloy is the main method to improve the comprehensive performance of aluminum alloy. In the purification process, the method of mixing the purification gas and the solvent and spraying th... -

OEM Manufacturer Graphite Price - Molded Graphite – Ningxin

Technical Characteristic Grade NX601 NX602 NX603 NX604 NX605 Grain Size (μm) 25 25 25 25 25 Bulk Density (≥g/cm3) 1.55 1.72 1.80 1.85 1.90 Compressive Strength (≥MPa) 35 45 60 70 80 Flexural Strength (≥MPa) 15 20 30 35 40 Porosity (≤%) 23 20 17 14 11 Specific Resistance (≤μΩm) 14 13 12 12 12 Ash Content (≤ppm) 800 700 600 500 300 Shore Hardness 35 45 50 55 60 ... -

Manufacturer of Solid Graphite Rod - Graphite semicircular boat – Ningxin

Square graphite boat The graphite boat itself is a kind of carrier, which can put the raw materials and parts that we need to position or shape together in it for high-temperature sintering. The graphite boat is made of artificial graphite through mechanical processing. So it is sometimes called a graphite boat, and sometimes it is called a graphite boat. Graphite half circle is mainly used in various vacuum resistance furnaces, induction furnaces, sintering furnaces, brazing furnaces, i... -

Fast delivery Graphite Rod Tube - Graphite plate – Ningxin

Graphite plate Graphite plate(graphite boat) adopts high-quality graphite material, adding organic compound with strong acid resistance. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment. It has extraordinary acid and temperature resistance. It is an ideal lining material for phosphoric acid reaction tanks and phosphoric acid storage tanks in the chemical industry. The product has the characteristics of wear resistance, temperature resistanc... -

Hot sale Factory Customized Graphite Boat - Graphite cluster wheel, Graphite roller – Ningxin

Technical Characteristic The graphite cluster wheel produced by Ningheda has the following advantages: 1. Thermal stability: According to the use conditions of graphite molds with rapid heating and cooling, special design has been carried out to ensure the reliability of product quality; 2. Corrosion resistance: The uniform and fine matrix design delays the corrosion of the graphite mold; 3. Impact resistance: The thermal shock strength that graphite can withstand is extremely high, so a... -

PriceList for Graphite Ingot - Graphite crucible – Ningxin

Ningheda Graphite material Advantages 1.Graphite raw material has high bulk density and low porosity, which resists the erosion of molten aluminum liquid and gaseous aluminum particles to the greatest extent. 2.Graphite raw material with high purity, low ash content prevents volatile substances in production, avoiding spots, holes on aluminum coated film, which can guarantee the quality of the aluminum coated film. 3.Graphite crucible has precise dimensions, smooth surface, strong oxidat... -

Newly Arrival China Isostatic Graphite Pot - Graphite parts – Ningxin

Technical Characteristic Application of graphite products: 1. Used as refractory material: Graphite and its products have the properties of high temperature resistance and high strength. It is mainly used in the metallurgical industry to make graphite crucibles. In steel making, graphite is often used as a protective agent for steel ingots and as an inner lining of metallurgical furnaces. 2. As a conductive material: used in the electrical industry to manufacture electrodes, brushes, car... -

-

Best-Selling Graphite For Vacuum Furnace - Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering – Ningxin

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering, Using the everlasting aim of “continuous quality improvement, customer satisfaction”, we are sure that our item excellent is secure and responsible and our products and solutions are best-selling at your home and overseas. With our rich experience a... -

Reasonable price High Frequency Induction Crucibles - EDM graphite – Ningxin

Technical Characteristic Compared with copper, EDM graphite has the following advantages: 1.Machining speed: high speed rough milling is 3 times of copper block, and high speed fine milling is 5 times of copper block. 2.Good machinability, complex geometric molding is available. 3.Light weight, low density (less than 1/4 of copper), easy to clamp. 4.It can reduce the number of single electrodes, because it can be bundled into composite electrodes. 5.Good thermal stability and no deformat... -

Excellent quality China Sintering Graphite Crucible - Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering – Ningxin

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Factory Directly supply China Graphite Boat Graphite Plate for Titanium Alloy Vacuum Furnace Sintering, Using the everlasting aim of “continuous quality improvement, customer satisfaction”, we are sure that our item excellent is secure and responsible and our products and solutions are best-selling at your home and overseas. With our rich experience a... -

2021 Latest Design Graphite Crucible Sizes - Graphite Raw Material – Ningxin

Technical Characteristic As the material of exothermic welding mold, graphite has the following characteristics: 1) High temperature resistance: The melting point of graphite is 3850±50℃, and the boiling point is 4250℃. Even if burned by ultra-high temperature arc, the weight loss is very small, and the thermal expansion coefficient is also very small. The strength of graphite increases with increasing temperature. At 2000°C, the strength of graphite doubles. The temperature of the chemi... -

Factory For Diamond Sintering Graphite Mould - Graphite cluster wheel, Graphite roller – Ningxin

Technical Characteristic The graphite cluster wheel produced by Ningheda has the following advantages: 1. Thermal stability: According to the use conditions of graphite molds with rapid heating and cooling, special design has been carried out to ensure the reliability of product quality; 2. Corrosion resistance: The uniform and fine matrix design delays the corrosion of the graphite mold; 3. Impact resistance: The thermal shock strength that graphite can withstand is extremely high, so a... -

China Cheap price Molded Graphite - Graphite heater – Ningxin

Technical Characteristic Main performance of graphite heater The oxidation speed and volatilization speed of graphite affect the service life of the heating element. When the vacuum degree is 10-3~10-4 mmHg, the operating temperature should be below 2300℃. In the protective atmosphere (H2, N2, Ar, etc.), the operating temperature can reach 3000℃. Graphite cannot be used in the air, otherwise it will be oxidized and consumed. The thermal expansion coefficient of graphite is small, and the... -

China Manufacturer for Making Graphite Molds - Molded Graphite – Ningxin

Technical Characteristic Grade NX601 NX602 NX603 NX604 NX605 Grain Size (μm) 25 25 25 25 25 Bulk Density (≥g/cm3) 1.55 1.72 1.80 1.85 1.90 Compressive Strength (≥MPa) 35 45 60 70 80 Flexural Strength (≥MPa) 15 20 30 35 40 Porosity (≤%) 23 20 17 14 11 Specific Resistance (≤μΩm) 14 13 12 12 12 Ash Content (≤ppm) 800 700 600 500 300 Shore Hardness 35 45 50 55 60 ... -

Factory selling Graphite Mould For Gold Bar Making From China - Graphite Box for anode powder – Ningxin

Our advantage 1. Thermal stability: for the use of hot and cold conditions, special treatment to ensure the reliability of product quality. 2. Corrosion resistance: uniform and fine material structure, delay the erosion of the use of degrees. 3. impact resistance: the ability to withstand high thermal shock, so the process can be assured. 4.Acid resistance: the addition of special materials significantly improved the physical properties of the material, excellent performance in terms of ... -

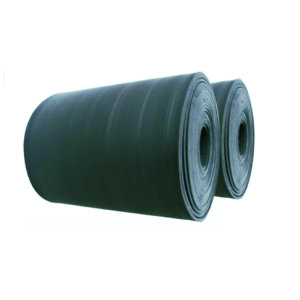

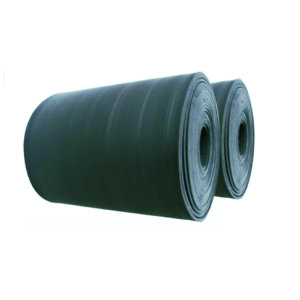

Factory wholesale Graphite Ingot Mold And Graphite Stirring Rod - Graphite felt – Ningxin

Graphite felt Graphite felt is divided into pitch-based graphite felt, polyacrylonitrile-based (PAN-based) graphite felt, and viscose-based graphite felt due to the different selection of original felts. The main purpose is to be used as heat preservation and heat insulation materials for monocrystalline silicon smelting furnaces. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents. Carbon felt is graphite felt after being treated at ... -

China Manufacturer for Carbon Graphite Calccination Crucible - Graphite heater – Ningxin

Technical Characteristic Main performance of graphite heater The oxidation speed and volatilization speed of graphite affect the service life of the heating element. When the vacuum degree is 10-3~10-4 mmHg, the operating temperature should be below 2300℃. In the protective atmosphere (H2, N2, Ar, etc.), the operating temperature can reach 3000℃. Graphite cannot be used in the air, otherwise it will be oxidized and consumed. The thermal expansion coefficient of graphite is small, and the...