factory Outlets for Carving Graphite Molds - Graphite felt – Ningxin

factory Outlets for Carving Graphite Molds - Graphite felt – Ningxin Detail:

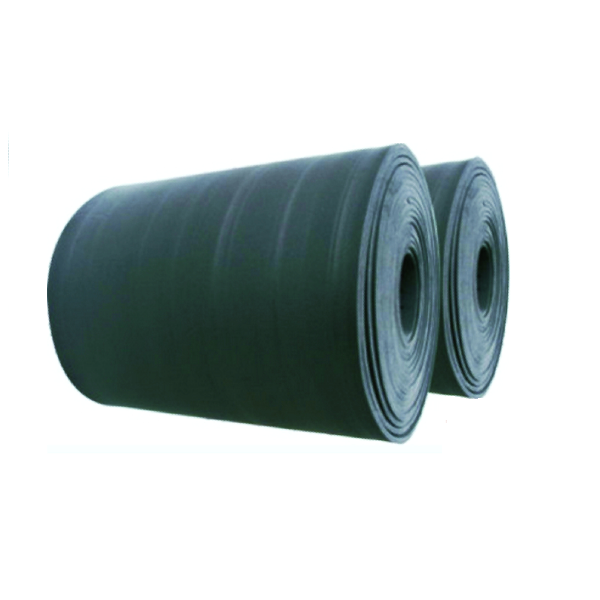

Graphite felt

Graphite felt is divided into pitch-based graphite felt, polyacrylonitrile-based (PAN-based) graphite felt, and viscose-based graphite felt due to the different selection of original felts. The main purpose is to be used as heat preservation and heat insulation materials for monocrystalline silicon smelting furnaces. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents.

Carbon felt is graphite felt after being treated at a high temperature of over 2000℃ under vacuum or inert atmosphere. The carbon content is higher than that of carbon felt, reaching more than 99%. At the end of the 1960s, graphite felt was already available in the world. Graphite felt is divided into pitch-based, polyacrylonitrile-based graphite felt and viscose-based graphite felt due to the different selection of the original felt.

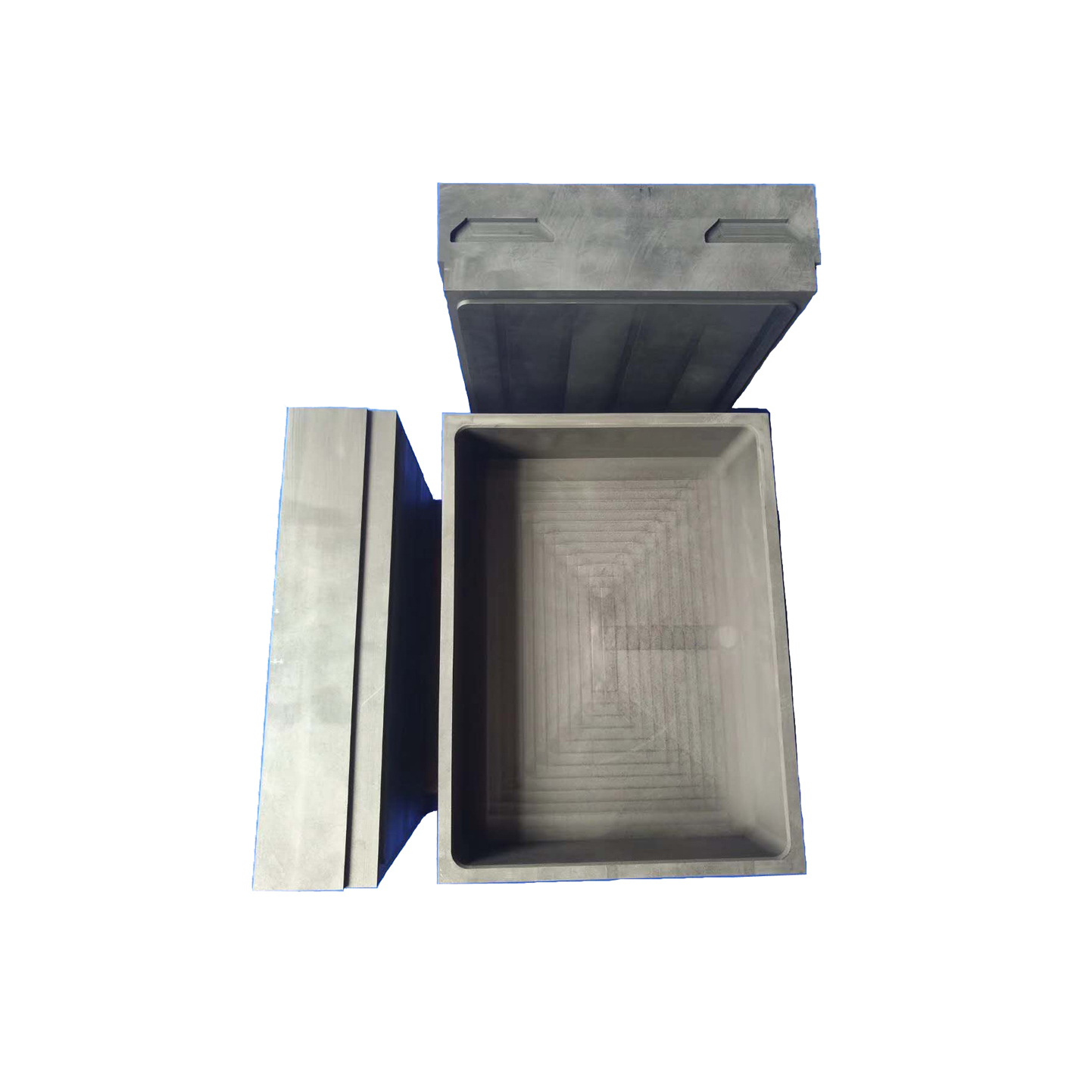

Among them, the asphalt represented by Kureha Chemical of Japan is the mainstream in the insulation industry [2], the European and American insulation felts are basically made of adhesives, while the majority of China uses polyacrylonitrile as raw materials. Process: Cut the polyacrylonitrile-based carbon felt or viscose-based carbon felt into the required size, roll it into a tube and put it into a container made of graphite material, and place the graphite container in a high-temperature furnace (the high-temperature furnace is a graphite tube furnace, an intermediate frequency , High-frequency induction furnace or other high-temperature furnaces with heating methods), protected by vacuum or high-purity inert gas, heated to 2200-2500°C at a heating rate of 100-300°C/h, and then naturally cooled to 100°C.

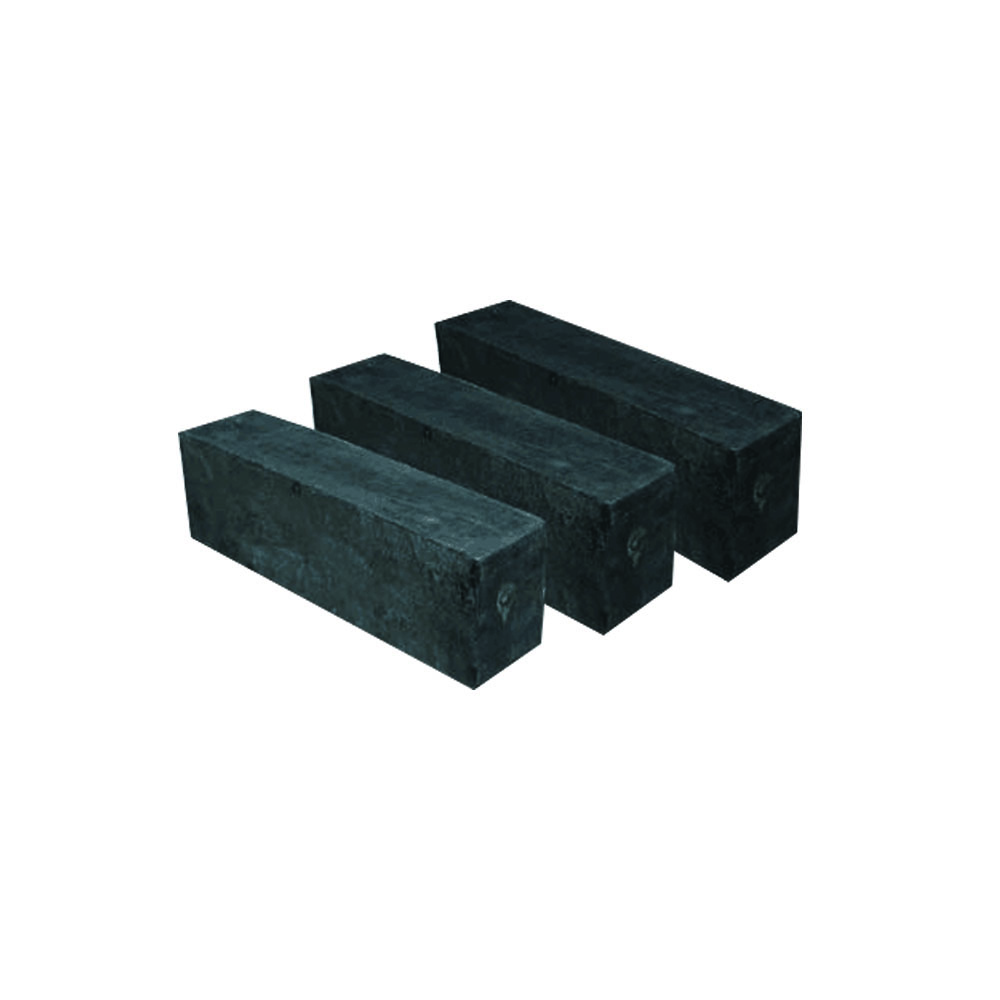

Graphite felt is strong and has strong oxidation resistance, but it has poor flexibility, high bulk density and good heat preservation performance. In addition to the characteristics of high purity, high temperature resistance, corrosion resistance, and non-melting of block graphite, they also have the advantages of being elastic, arbitrarily folding, cutting, and sewing with graphite yarn. The main purpose of graphite felt is as a heat preservation and heat insulation material for single crystal silicon smelting furnace. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents. Graphite felt can be used at a temperature of about 3000°C in a non-oxidizing atmosphere.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for factory Outlets for Carving Graphite Molds - Graphite felt – Ningxin , The product will supply to all over the world, such as: Italy, Ireland, Oman, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.