Factory For China High Density Graphite Plate for Tungsten Cemented Carbide Powder Sintering

we could supply high quality solutions, aggressive value and greatest customer support. Our destination is “You come here with difficulty and we provide you with a smile to take away” for Factory For China High Density Graphite Plate for Tungsten Cemented Carbide Powder Sintering, We have been anticipating to cooperate along with you around the foundation of mutual rewards and common enhancement. We’re going to never disappoint you.

we could supply high quality solutions, aggressive value and greatest customer support. Our destination is “You come here with difficulty and we provide you with a smile to take away” for China Graphite Sintering Mold, Sintered for Cemented Carbide, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

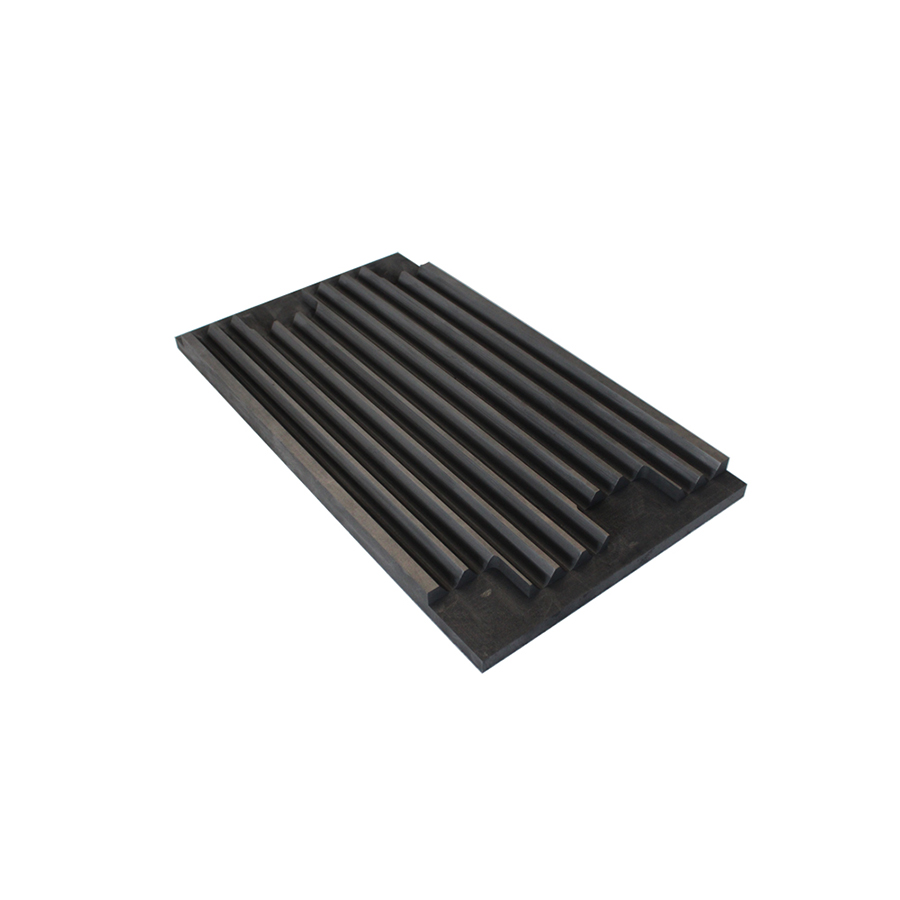

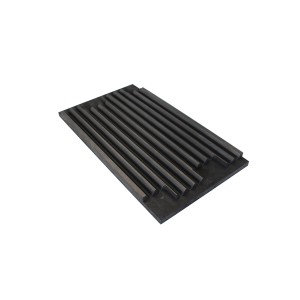

Graphite plate

Graphite plate(graphite boat) adopts high-quality graphite material, adding organic compound with strong acid resistance. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment. It has extraordinary acid and temperature resistance. It is an ideal lining material for phosphoric acid reaction tanks and phosphoric acid storage tanks in the chemical industry. The product has the characteristics of wear resistance, temperature resistance, pressure resistance, corrosion resistance, creep resistance, oil-free self-lubrication, small expansion coefficient, and superior sealing performance.

1. Excellent corrosion resistance

The product adopts high-quality graphite material and adds an organic compound with strong acid resistance, which effectively reduces the porosity of the product and increases the volume density of the product. Therefore, the product has excellent corrosion resistance and strong wear resistance.

2. Stable performance and strong durability

The product uses high-strength organic glue as a binder and introduces high-tech additives at the same time, so the product has high strength, good wear resistance, and extremely stable structure. The product structure does not change with temperature changes.

3. Accurate dimensions

Using compression molding, the product has good molding quality and precise dimensions, and can produce special products according to user requirements, which can fully meet the requirements of construction and masonry technology.

Graphite plate (graphite boat) are widely used in powder metallurgy and cemented carbide sintering. It includes a number of W-shaped bidirectional chute with two opposite groove surfaces and bottom supporting protrusions, a bottom surface, an upper end surface, an inner side surface, an outer side surface and a stop opposite to the upper end surface. The two opposite groove surfaces are respectively designed with At least one exhaust through groove, the intersection of the bottom supporting protrusion and the two opposite groove surfaces are respectively designed with an edge protection groove. The bottom surface is designed with a through groove parallel to the W-shaped two-way chute and the cross-sectional shape is approximately Λ-shaped at the lower part of the protrusion formed by any two adjacent W-shaped two-way chute grooves. The utility model makes the hard alloy long thin sheet products uniformly degummed during the hydrogen degumming and vacuum sintering process, avoids product warpage and deformation, and has a large product load and few consumables.

The graphite plate of Jiangxi Ningheda New Material Co., Ltd. has high processing precision, excellent material, high temperature resistance, corrosion resistance and long service life.we could supply high quality solutions, aggressive value and greatest customer support. Our destination is “You come here with difficulty and we provide you with a smile to take away” for Factory For China High Density Graphite Plate for Tungsten Cemented Carbide Powder Sintering, We have been anticipating to cooperate along with you around the foundation of mutual rewards and common enhancement. We’re going to never disappoint you.

Factory For China Graphite Sintering Mold, Sintered for Cemented Carbide, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Any questions, pls contact Alisa, +86-18370509070, alisa(at)nhdcarbon(dot)com

Q1. Are you a factory or trading company?

A: We are an ISO9001-Qualified processing manufacturer with 70000 square meter factory area.

Q2. Can you introduce your main products?

A: Sure.

Jiangxi Ningheda New Material Co., Ltd. mainly produces graphite products, we can offer customized shape according to customers’ specific demand. Our Graphite Products, including molded graphite products, isostatic graphite products, extruded graphite products, vibration moulding graphite products. We can produce a lot of graphite products, like graphite mold, graphite casting die, graphite heating element, graphite crucible, graphite sealing ring, graphite tube, graphite rod, graphite edm, graphite block etc.

Q3.What is your MOQ?

A: 1 piece (graphite block, graphite rod, graphite box, graphite mold, graphite material, graphite seal ring, graphite crucible, graphite products, graphite sintering mold, graphite heater etc.).

Q4. Can you offer free samples?

A: Yes, usually we can offer free samples for customers to check the quality, but do not afford express charge.

However, if the sample is expensive, we have to charge basic cost of the sample. And samples delivery time is 3-10 days usually.

Q5. When can I get the price?

A: We will reply you within 24 hours after getting your detailed requirements, like size, quantity etc. If you need an urgent response, pls call us directly.

Q6. Do you accept OEM or ODM orders?

A: Yes, of course, most of our products are customized.

Q7. How about your delivery time?

A: Usually 7 to 25 days after advance payment.

Q8. Do you test your goods before delivery?

A: Yes, we have strict inspection system.

Q9. How do you keep long-term business relationship?

A: 1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Remark: When you contact us, please show us the accurate drawing(s) and your selected graphite material information, then we can offer you accurate price(s).